“Safety Work Gloves: Your Trusted Partners in Workplace Protection”

Introduction: Safety work gloves are the unsung heroes of workplace safety, standing as a vital element of personal protective equipment (PPE) that protects individuals from an array of occupational hazards. Irrespective of your industry – whether you’re in construction, manufacturing, or any other field – choosing the right safety gloves is paramount in reducing the risk of injuries and enhancing overall workplace safety. In this comprehensive guide, we will explore the significance of safety work gloves, delve into the various types available, and provide expert insights on selecting the perfect pair to ensure your safety on the job.

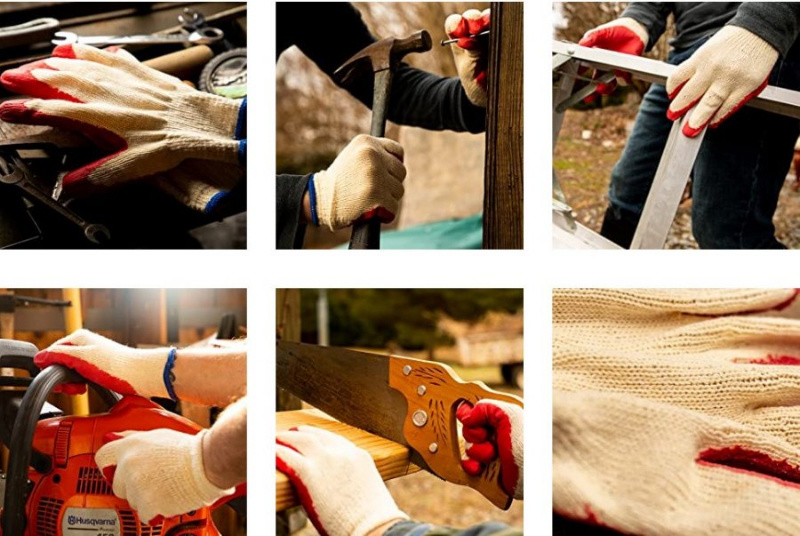

1. The Critical Role of Safety Work Gloves Safety work gloves are your guardians at the workplace, serving multiple critical functions, including:

Protection against cuts, punctures, and abrasions.

Insulation from extreme temperatures.

Resistance to hazardous chemicals.

Enhanced grip and dexterity.

Safeguarding against electrical hazards.

2. Diversity in Safety Work Gloves Safety work gloves come in various types designed to address specific workplace risks:

Cut-Resistant Gloves: Ideal for industries dealing with sharp objects, such as construction and metalworking.

Heat-Resistant Gloves: Essential when working in high-temperature environments, like welding or foundries.

Chemical-Resistant Gloves: Crucial for protection against harmful chemicals, commonly found in laboratories and chemical plants.

Electrically Insulated Gloves: Vital for electrical workers to prevent electric shocks and burns.

General-Purpose Gloves: Versatile gloves suitable for light to medium-duty tasks across various industries.

3. Selecting the Right Safety Work Gloves Choosing the appropriate safety work gloves involves a systematic assessment of several key factors:

Hazard Assessment: Identify specific workplace risks to determine the required level of protection.

Material: Opt for gloves made from materials tailored to the particular hazards you face, such as leather, Kevlar, or rubber.

Size and Fit: Ensure your gloves provide a comfortable fit, allowing dexterity without being too tight or loose.

Durability: Invest in gloves designed to withstand the demands of your job, ensuring they remain effective over time.

Compliance: Verify that your selected safety gloves meet relevant safety standards and regulations.

4. Maintenance and Care Proper maintenance of your safety work gloves is essential to ensure their longevity and effectiveness. Regularly inspect and clean your gloves, and replace them when signs of wear and tear appear.

Conclusion: Safety work gloves are not just accessories; they are your trusted allies in establishing a safe and productive work environment. The right pair of gloves can be the determining factor between safety and potential accidents and injuries. By understanding the diverse types of gloves available and selecting the most suitable pair for your specific job, you are taking a significant step toward enhancing workplace safety.